Processing...

The Combustion Engine Calculator provides formulas for engine mechanics and performance tuning. These include measurements for total displacement (volume) of cylinders and components, bore, rod length, stroke, and ratios commonly used in performance tuning. The Engine calculator provides useful formulas and equations used in performance engine tuning including the calculation of key ratios and volumes. This page also include general information on combustion engines.

Engine RATIOS AND LENGTHS:

- Bore (diameter): Compute the Bore Diameter based on the engine displacement, number of cylinders and the stroke length.

- Bore Stroke Ratio: Compute the Bore Stroke Ratio based on the diameter of the bore and the length of the stroke.

- Compression Ratio: Compute the Combustion Ratio base on the minimum and maximum displacements of the cylinder at the beginning (1-Induction) and compressed (3-Power) portions of the combustion cycle

- Displacement Ratio: Compute the Displacement Ratio based on the volumes at the beginning and end of the stroke.

- Rod Length Stroke Ratio: Compute the Rod and Stroke Length Ratio base on the two lengths.

- Stroke (length): Compute the Stroke Length based on the total engine displacement, number of cylinders and the bore.

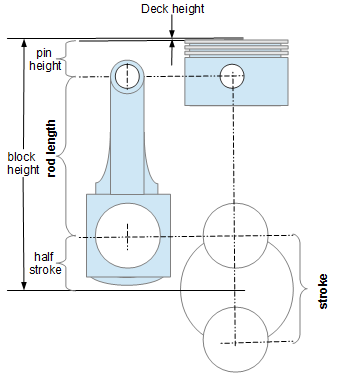

- Piston Position: Computes the Piston Position based on the crank angle, crank radius, and rod length.

- Piston Deck Height: Computes the Piston Deck Height based on Block Height, Rod Length, Stroke Length, and Pin Height.

Engine VOLUMES:

- Total Engine Displacement:

Compute the Total Volume (displacement) of a Combustion Engine based on the bore, stroke and number of cylinders.

Compute the Total Volume (displacement) of a Combustion Engine based on the bore, stroke and number of cylinders. - Engine Cylinder Volume: Compute the Volume (displacement) of a Engine Cylinder based on the bore and stroke.

- Engine Cylinder Overbore Volume: Compute the Volume (displacement) of an Engine with an Overbore based on the stroke, bore, overbore and number of cylinders.

- Rotary Engine Equivalent Displacement: Compute the Equivalent Volume of a Rotary Engine based on the swept volume and number of pistons.

- Compression Volume (V2): Compute the Compressed Volume of a Cylinder when the piston is at the end of the stroke and the chamber is at its smallest (and most compressed) volume, based on the chamber, deck, crevice, chamfer, gasket, valve relief and dome/dish volumes. This is the second volume (V2) in the Compression Ratio calculation.

- Gasket Volume: Compute the Volume of a Gasket based on the inner and outer diameters and the gasket's thickness.

- Deck Volume: Compute the Volume of a Cylinder Deck based on the deck height and the bore.

- Crevice Volume: Compute the Volume of a Cylinder Crevice based on the piston diameter, cylinder bore and the crevice height.

- Chamfer Volume: Compute the Volume of a Cylinder Chamfer based on the cylinder diameter and the chamfer height and width.

Engine SPEEDS AND RPMS:

- Piston Speed: Piston Speed (mean) based on stroke length and RPMs.

- Max Piston Speed: Max Piston Speed based on stroke length and RPMs

- RPMs: RPMs based on desired piston speed and stroke length.

Other Automotive Calculators

- Camber Angle

- Camber Offset

- Breakover angle - Ground clearance between axles

- Approach angle - Ground clearance in front of or behind vehicle.

- Carburetor Air Flow - computes the airflow rate based on engine size, rpms and efficiency

Reference

- Performance Automotive Engine Math (John Baechtel), CarTech, Inc., Publishers. 2011

- Auto Math Handbook (John Lawlor), HPBooks 1992

- Wikipedia - https://en.wikipedia.org/wiki/Internal_combustion_engine